Industry news

Instruction for the 3 most commonly used costings: PTFE, PFA and Silicon

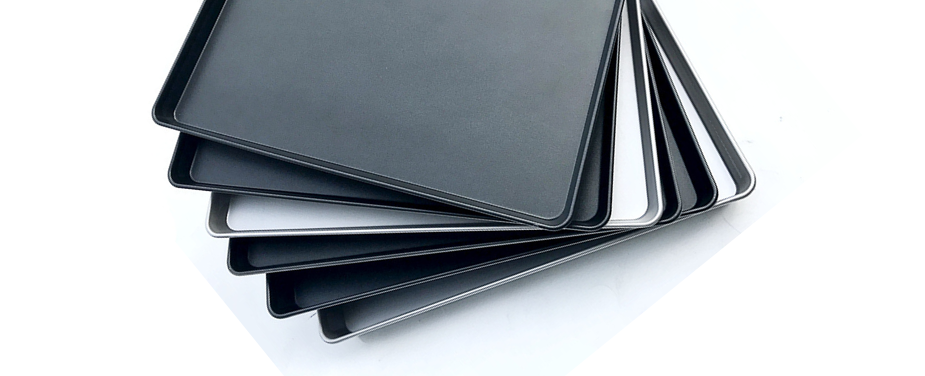

The followings are 3 commonly applied nonstick coatings for baking pans: PTFE, PFA and Silicon

1. PTFE is the most popularly applied coating to commercial baking pans(but only good for bread that contains less than 11% of sugar. For high sugar content, only silicon coating works). With a requested temperature, the fluoropolymers and other agents form to a smooth and non-stick PTFE coating. PTFE can be continuousely baked below 260°C while still keep good conditions. With its characters of low coefficient of friction and good chemical etching and abrasion resistance, PTFE release performance is very good.

2. PFA ( powder coating ) is one of the best and top segment market release coatings. PFA coating is more durable and provides more than 2500-3000 cycles of life span. PFA is the most suitable for commercial bread baking. The coating cost of PFA is much higher than the coating cost of PTFE, but the life span is much longer than that of PTFE, therefore, the overall production cost is lower for PFA coated baking pan.

3. Silicone coating is recommended for dough with high sugar content like muffins or cakes. Compare with PTFE coating, silicon service life is shorter. For dough with more than 20% sugar contents, suitable amount of grease oil is recommended. The silicone coating become soft at high temperature, therefore, never touch the silicon coating with sharp things.

RELATED NEWS

CATEGORIES

CONTACT US

Contact: David

Phone:

E-mail: sales@lidabakeware.com

Whatsapp:+86 17701703625

Add: 5th Floor, No.1 Building,No.6 Kangye Road,Zhujiajiao Town, Qingpu District, Shanghai, China